Tools for the Coin Mints

WORLD CLASS TOOLS FOR COIN MINTS

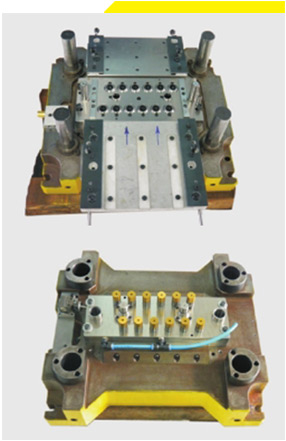

BLANKING TOOLS FOR SCHULER BLANK MASTER

SAK-125 & SAK-160

- The Tool is designed for Schuler Blank Master SAK-125 / SAK-160, maximum Speed 700 to 750 SPM.

- T Slots, Locating Holes of the Master Die Set matches with the Press

- 12/13 Cavity Blanking Tool for SAK-125 & 16/20 Cavity for SAK-160

- Interchangeable Carbide Punches and Dies. TIN Coated Punches offered for better Tool Performance.

- Projected Die Design eliminates replacement of Die Holder Plate

- Provision for Coolant Supply is given to the Stripper Plate and the Compressed Air Supply is given to the Punch Holder.

- Miss Feed Detectors / Security Pins & Sensor are provided to Stop the Press in case of any miss feed.

- Tool can be designed to accommodate the Cartridge Block.

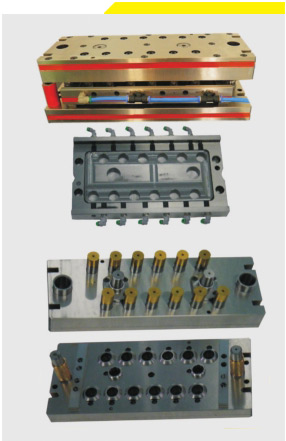

CARTRIDGE BLOCK FOR BLANKING TOOL

The Cartridge Block will hold the Punches and Dies and can be easily fixed to the Mother Die Set. Keeping the Mother Die Set clamped to the Press the Cartridge Block can be taken out for Punch / Die re-grinding. With Two Cartridge Blocks, the requirement of Spare Blanking Tool will not arise.

The Cartridge Block can be handled with one or two technicians.

The Loading / Unloading, Tool Setting, Re-grinding and Tool maintenance get very much simplified.

The Cartridge Block can be run upto 700 SPM. The Coolant Supply is given to the Stripper Plate & Compressed Air Supply is through the Punch Holder.

Carbide Punches and Die are made to suit the Customers specification.

The Punches can be TIN coated for better performance

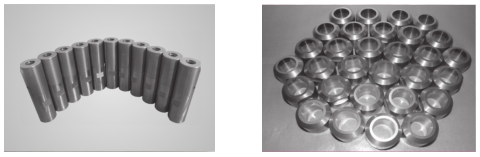

Reed Forming Collars are made in Die Steel (D2) and Tungsten Carbide.

The life of TC Collars is much higher than the Die Steel Collars

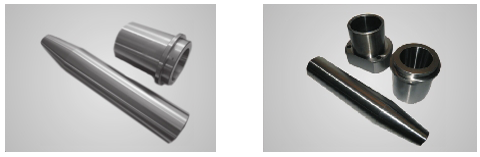

Interchangeable Guide Bushes and Guide Pillars made with High Quality Bearing Steel. Guide Pillars with Toughned Core & Hardened bearing surface (60 HRC) gives long lasting life.